3d printed titanium material properties

4D printing involves the use of 3D printing techniques for printing smart materials ie single material multi-material or non-active material. Generally 3D bioprinting can utilize a layer-by-layer method to deposit materials known as bio-inks to create tissue-like structures that are later.

Mechanical Properties Of 3d Printed Multi Material Components Download Table

Approaching intrinsic dynamics of MXenes hybrid hydrogel for 3D printed multimodal intelligent devices with ultrahigh superelasticity and temperature sensitivity.

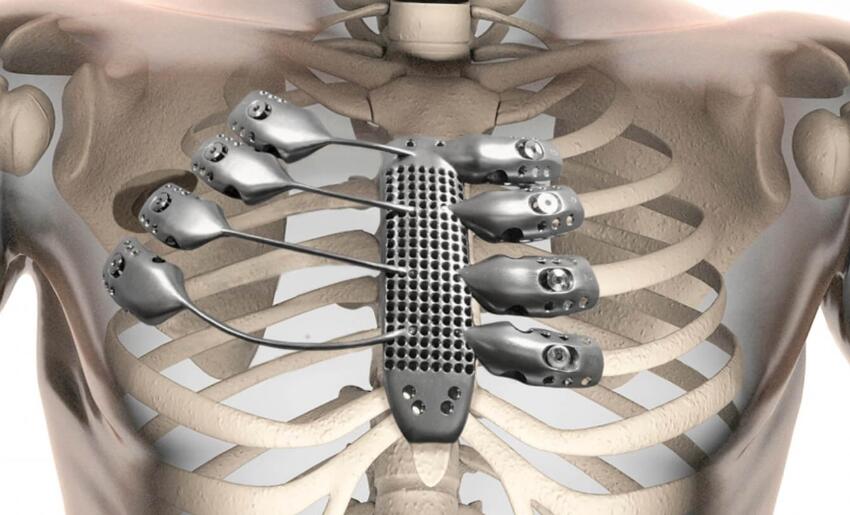

. Three dimensional 3D bioprinting is the utilization of 3D printinglike techniques to combine cells growth factors andor biomaterials to fabricate biomedical parts often with the aim of imitating natural tissue characteristics. Metal 3D printing works very similarly to other 3D printing processes. These structures can self-assemble self-repair and are self-compatible with changes.

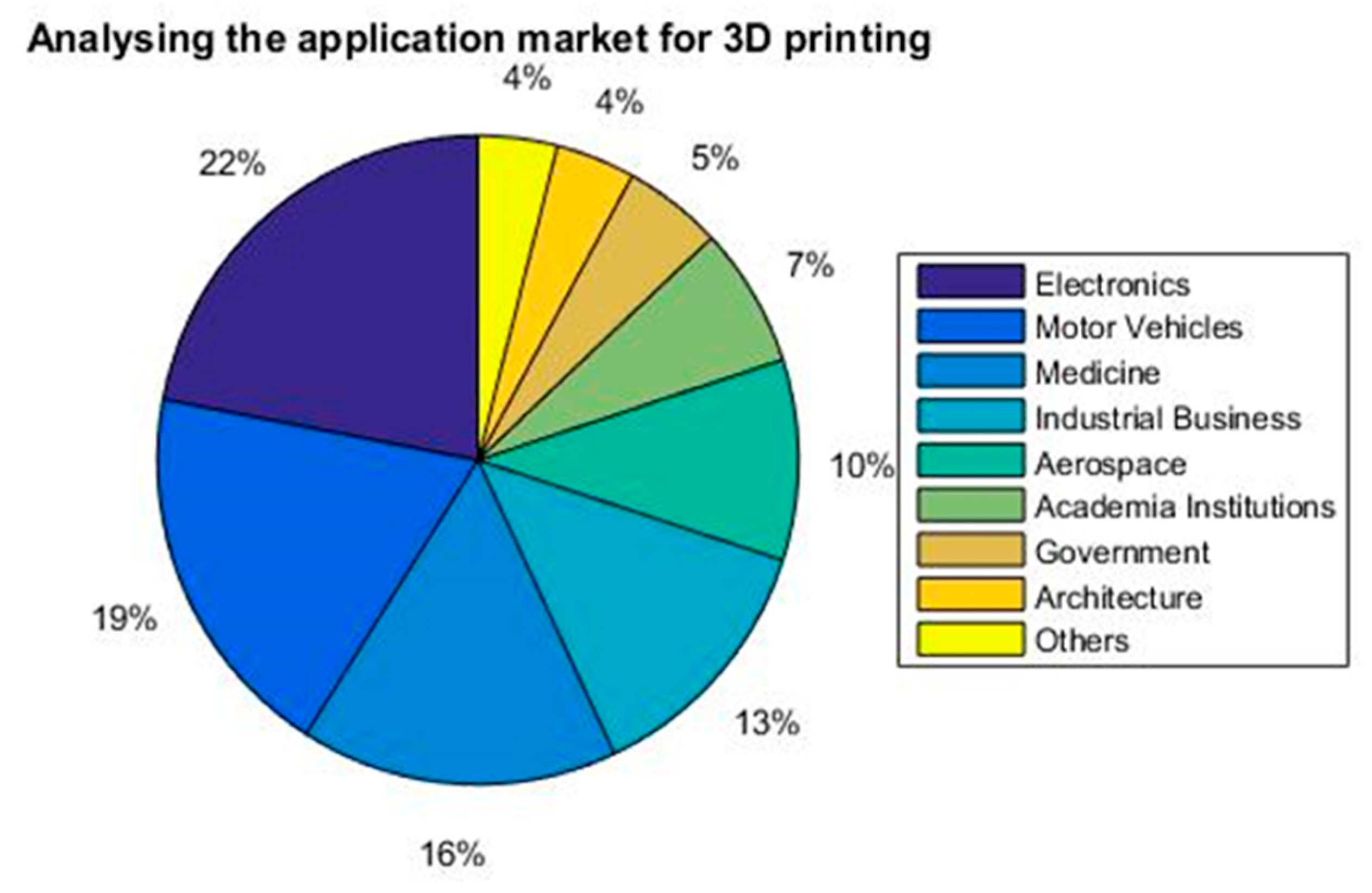

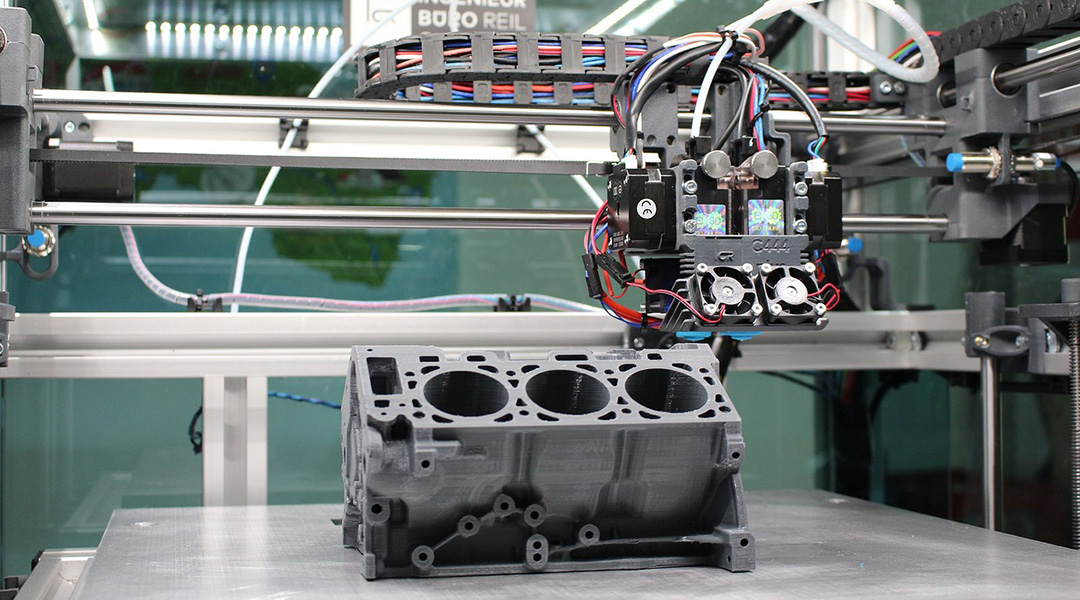

The number of companies selling AM systems went from 49 in 2014 to 97 in 2016 amongst the 49 involved with metal AM This technology has been used predominantly for research prototyping or advanced applications in the aerospace industry. The number of available 3D printing materials grows rapidly every year as market demand for specific material and mechanical properties spurs advancements in material science. 3D printing or additive manufacturing is the construction of a three-dimensional object from a CAD model or a digital 3D model.

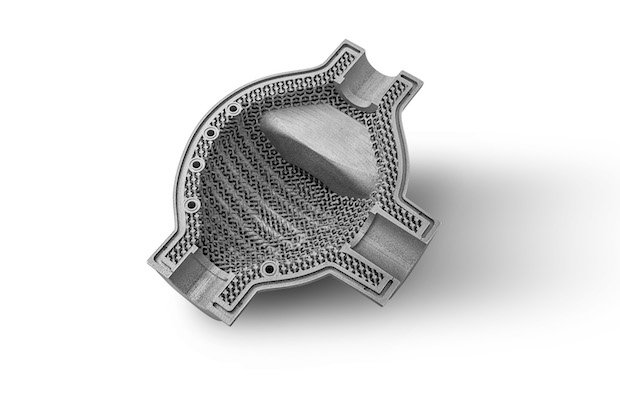

Liu H Du C Liao L. Metal 3D printing. After a simple post-heat treatment on a commercial titanium alloy adequate elongation and tensile strengths over 1600 MPa are achieved the highest specific strength among all 3D printed metal to date.

This work paves the way to fabricate structural materials with unique microstructures and excellent properties for broad applications. As an example 3D-printed graphene electrodes with a porous and interconnected structure exhibited the desired electric double-layer capacitor behaviour and showed an outstanding rate capability. Threaded fasteners allow quick assembly and disassembly granted the threading has been designed and printed properly and provide robust connectivity so.

After the part is 3D printed. Versus Ti grade 23 annealed the mechanical properties of Ti6Al4V are comparable to wrought titanium for tensile strength elongation and hardness. 591 Porsches 3D-Printed Custom Seats.

3D-printed Martian rock and titanium alloy could be used on Mars to make rocket parts. Our lead time options lend you flexibility. It can be done in a variety of processes in which material is deposited joined or solidified under computer control with material being added together such as plastics liquids or powder grains being fused typically layer by layer.

Material jetting 3D printers are equipped with various inkjet printheads somewhat similar to. This metal 3D printer is dedicated to Titanium 3D printing but Copper is in the pipeline as well. 400mm x 800mm x 500mm.

Washington State University researchers managed to produce 3D printed parts from Mars regolith and titanium alloy. This makes it impossible to give a complete overview of all 3D printing materials but each 3D printing process is only compatible with certain materials so there are. Its laser beam power is equal to 45 kW partly explaining the printers high melting capacity and productivity.

3D-printed Parts on Your Schedule. Although there are several different metal 3D printing services the most common ones use technologies similar to selective laser sintering. 245mm x 245mm x 330mm.

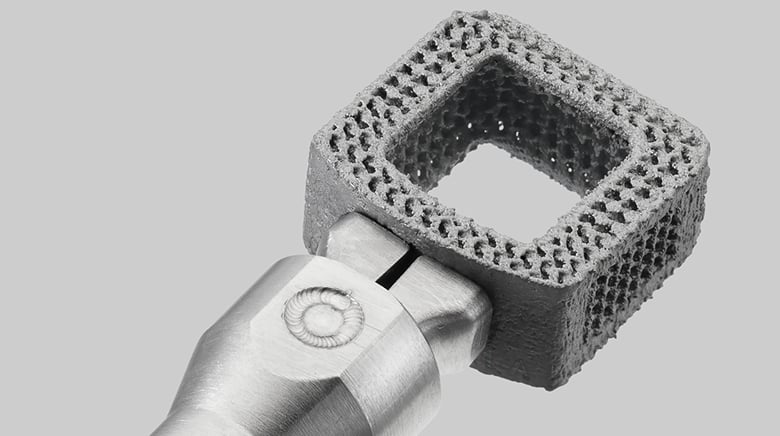

Titanium Ti6Al4V is a workhorse alloy. Metal additive manufacturing is showing excellent perspectives of growth. DMLS parts are typically characterized as having strength hardness and durability that is at the least comparable to cast or forged parts in a.

I3DMFGs EOS M280 and M290 DMLS machines use 20 to 60 micron powders and 400W lasers to fuse micro-layers of fine metal together at specific points directed by a 3D Solidworks design file to produce production parts. The limited availability of 3D printing material suppliers compels customers to buy proprietary material from big players which results in high costs. Request an online quote today.

Need printed parts lightning fast. Threaded fasteners such as screws and inserts are a popular method for securing 3D-printed parts together. 4D printing finds its applications in medical sciences soft robotics self-healing products active origami etc.

Metal printing has a dimensional tolerance of 01 mm. Get quality metal 3D-printed prototypes and production parts. Explore material properties available for plastic and metal 3D printing processes.

Metal powders are heated and fused together into layers. Titanium Inconel Cobalt Chrome Copper.

Titanium For Industrial 3d Printing Eos Gmbh

Titanium 3d Printing The Ultimate Guide All3dp Pro

Metals Free Full Text Development Of Am Technologies For Metals In The Sector Of Medical Implants Html

Titanium Ti 6al 4v 3d Printing Get Custom Metal 3d Parts Fast

Mechanical Properties Of 3d Printed Multi Material Components Download Table

Applications Of Titanium Alloy 3d Printing Technology Refractory Alloys

Titanium 3d Printing The Ultimate Guide All3dp Pro

Titanium Ti6al4v Metal 3d Printing At Materialise

Mechanical Properties Of Commercially Pure Titanium And Its Alloys Download Table

A Guide To 3d Printing With Titanium Amfg

Transforming Titanium With 3d Printing Uw College Of Engineering

Fit Ag And Caterpillar Inc Join Forces To 3d Print Aluminium And Titanium Parts Tct Magazine

Mechanical Properties Of Biomedical Titanium Alloys Download Table

Titanium 3d Printing The Ultimate Guide All3dp Pro

A New Copper Titanium Alloy Enables 3d Printing Advanced Science News

A Guide To 3d Printing With Titanium Amfg

When Bad Makes Good Defects Strengthen 3d Printed Material Cornell Chronicle

Mechanical Properties Of 3d Printed Multi Material Components Download Table